Leveraging Scenario Planning for S&OP Decision Support

Sales and Operations Planning has become the preferred method to facilitate clear and formal communication between the demand and supply sides of a business. However, one-third of SCP leaders cite “the lack of effective decision making in the S&OP meeting process as the most critical problem to solve for their function’s overall performance” (source: Gartner, Improve S&OP Decision Making Through Scenario Planning, Supply Chain Research Team, 4 May 2020). To address this, Gartner advises organizations to adopt scenario planning for S&OP. Read on to explore the benefits and how you can apply this in your organization.

S&OP as a practice is changing

We have written extensively about how S&OP is changing. There have been significant advances in both technology and supply chain thinking since the methodology originated in the late 1980s. For one, the market is moving quickly to place increased value on the analytical component of S&OP. Scenario planning capabilities, powered by prescriptive analytics, can provide more actionable and exciting insights for planning meetings. These insights are also increasingly valuable at a time when we’re seeing more demand volatility and business disruption. Thinking in scenarios reduces the response time required to adapt to changing business conditions, building resilience into the planning process. Scenarios also allow organizations to model how they can ‘bridge the gap’ between their current position and their strategic plan, identifying the actions required to deliver opportunities and mitigate any vulnerabilities. Unlike many ERP systems, where you can only look at one scenario at a time, Apps like AIMMS S&OP Navigator let you assess multiple scenarios simultaneously, which is even more insightful.

Scenario planning capabilities, powered by prescriptive analytics, can provide more actionable and exciting insights for planning meetings. – Tweet this

How does this work in practice?

In “Improve S&OP Decision Making Through Scenario Planning,” Gartner outlines a step-by-step approach to build scenario planning capabilities in S&OP which can be summarized as follows:

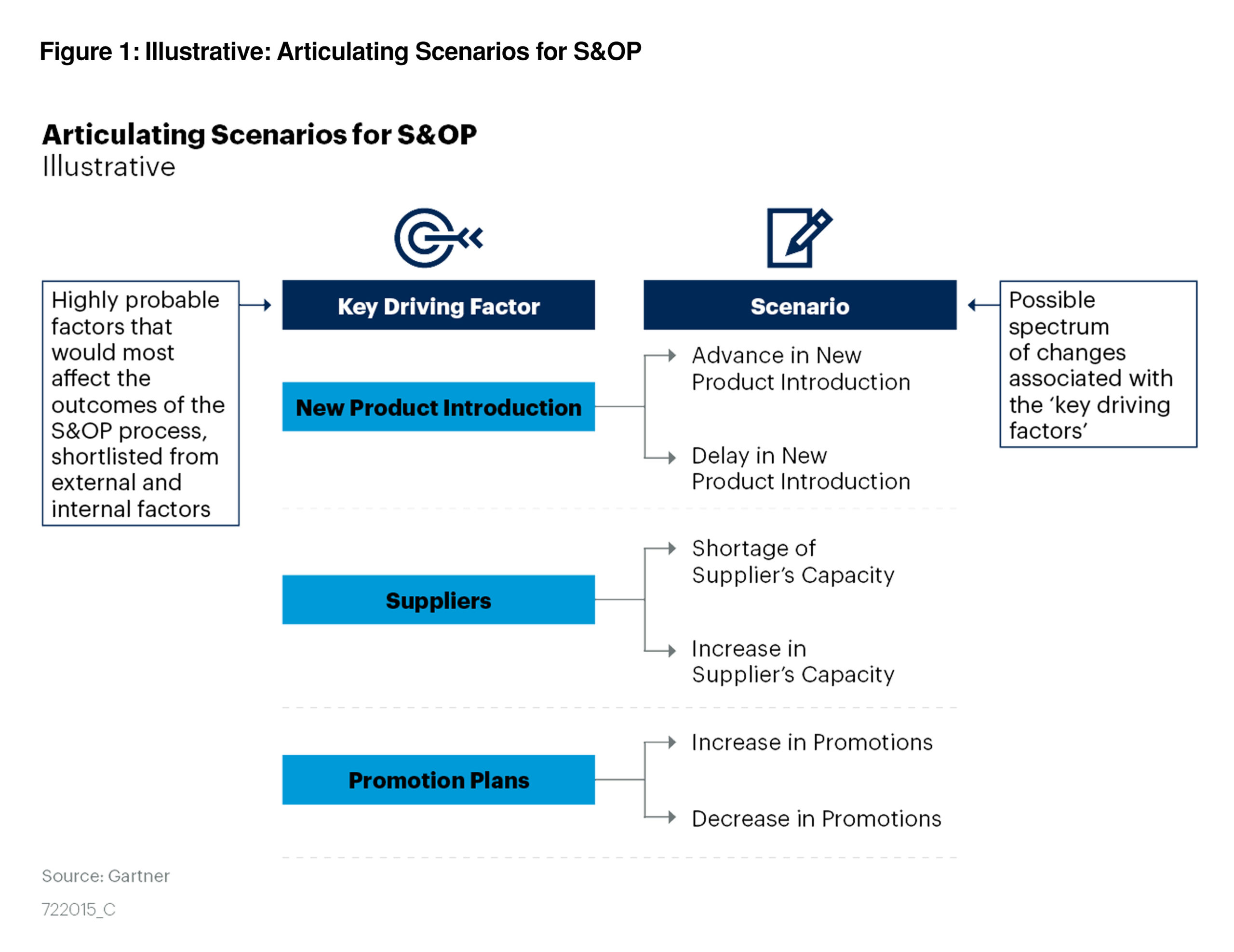

- Develop scenarios based on the key driving factors, such as new product introductions, suppliers, changing promotion plans, etc (as illustrated in Figure 1 below);

- Assess the business impact, risks and opportunities of prioritized scenarios. These can be discussed in the executive meeting.

- Define indicators to monitor changes in scenarios.

COVID-19 is clearly a pressing factor impacting many organizations at the moment. Let’s explore how leveraging scenario planning for S&OP can assist in your business’ COVID-19 recovery.

COVID-19 and Scenario Planning

In the current context, you may benefit from studying multiple resource utilization what-if scenarios to accommodate your production plan accordingly. Using AIMMS S&OP Navigator, you can quickly simulate the impact of capacity shutdowns and study other resource utilization scenarios to ensure resource requirements. This can be done during meetings themselves to add agility to the decision-making process.

Another likely scenario today is the need to adopt new customer channels, for instance online grocery. These channels might not be able to adapt as quickly to volatile shifts in demand. With S&OP Navigator you can also prioritize certain channels and visualize the impact on your resources and margin.

These are just two among many examples of how scenario planning can bolster S&OP decision making. If you’d like to learn more, download Gartner’s “Improve S&OP Decision Making Through Scenario Planning.”