In today’s volatile business landscape, supply chain leaders are under unprecedented pressure to deliver efficiency, resilience, and sustainability.

The Harvard Business Review’s article, In Turbulent Times, Consider Strategic Subtraction talks about a bold approach: instead of adding complexity, organizations should focus on what to subtract—be it products, processes, or supply chain nodes—to sharpen focus and unlock value.

Why Strategic Downsizing Matters

For years, supply chains have grown more complex—more SKUs, more facilities, more paths to market. This complexity can erode margins, slow response times, and increase risk.

Strategic subtraction is the deliberate removal of underperforming or redundant elements to create a leaner, more focused, and more sustainable supply chain.

Recent research underscores the strategic importance of product deletion as part of supply chain management. While innovation and expansion have historically dominated product management, the removal of products—especially those that are low-margin, slow-moving, or resource-inefficient can yield outsized benefits.

Let’s dive into the most important strategic objectives for supply chain leaders related to downsizing.

- Leanness and Waste Reduction: SKU reduction directly supports lean supply chain objectives by reducing waste, simplifying processes, and focusing resources on high-value activities.

- Sustainability Gains: Eliminating products with poor resource efficiency can make supply chains more eco-efficient, reducing both waste and carbon footprint. Lean and green initiatives are often mutually reinforcing fewer products mean less material usage, transportation, and emissions.

- Cross-Functional Decision Making: Effective subtraction requires input from marketing, operations, finance, and sustainability teams. A structured and data-driven decision process can help organizations weigh the trade-offs and select the right candidates for deletion.

- Complexity vs. Performance: There is an inverted U-shaped relationship between product portfolio complexity and organizational performance. Too much complexity can hurt performance, but so can excessive simplification. The challenge is to find the optimal balance through data-driven analysis and scenario planning.

Watch a short clip from my interview with Darren Bellerby, a Global Supply Chain Optimization leader at Sika, where he explains how his team managed to reduce their warehouse complexity in Japan, using SC Navigator.

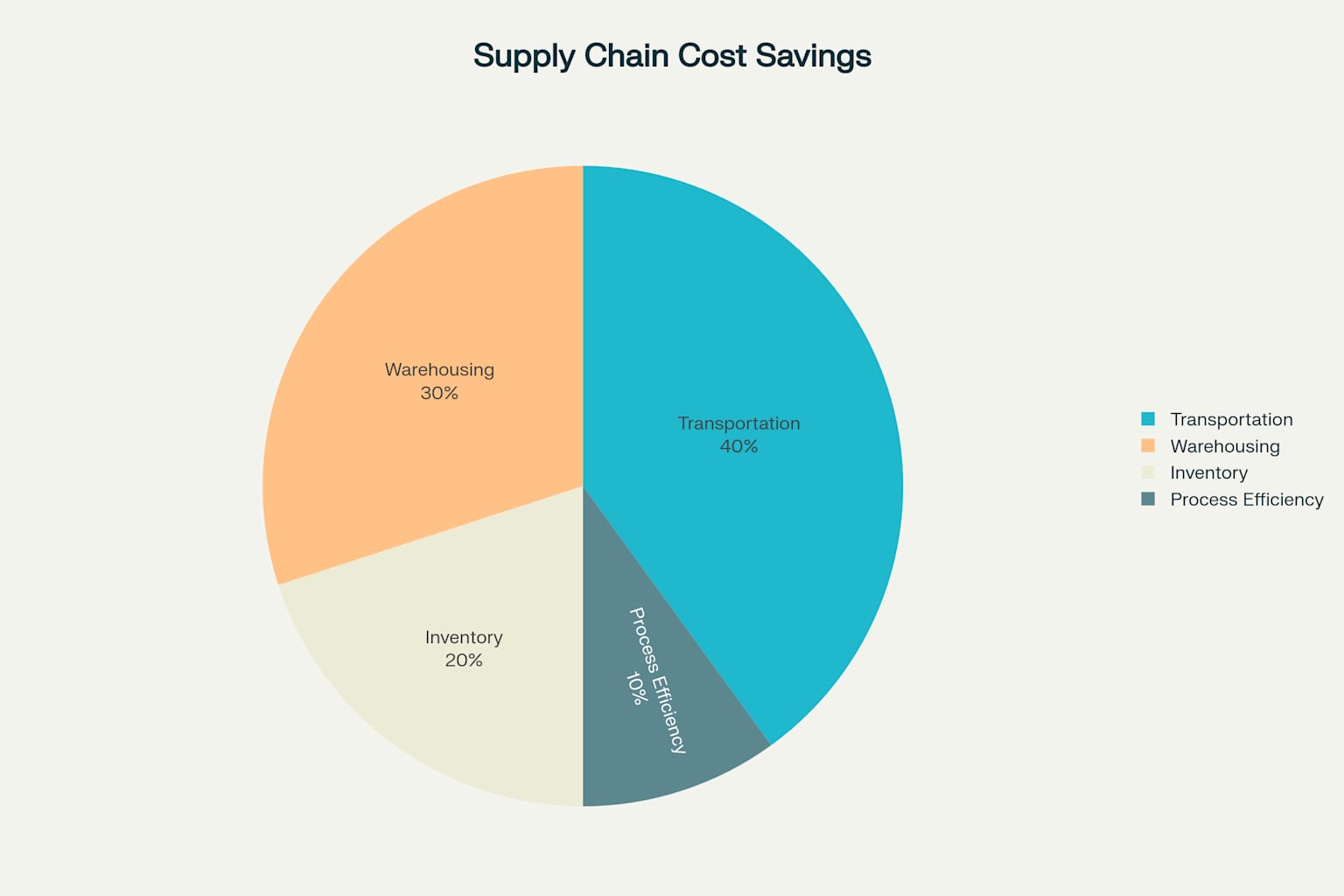

Cost Savings Breakdown: The Impact of Strategic Subtraction

A data-driven approach to subtraction is essential. Supply chain network optimization and product portfolio rationalization can deliver significant cost savings across multiple categories. Our data indicates where these savings typically accrue:

How Network Design and Optimization Support Strategic Subtraction

Effective network design and optimization provide the analytical foundation and practical moves that supply chain leaders need to make informed, data-driven subtraction decisions that enhance efficiency and align with strategic goals.

1. Baseline Mapping and Opportunity Identification

Network design tools map the current state of the supply chain—highlighting cost, service, and risk drivers. This baseline helps leaders identify underperforming products, redundant facilities, or suppliers that add complexity without value.

2. Scenario Modeling and Impact Analysis

Advanced optimization platforms enable scenario modeling. Leaders can simulate the impact of deleting a product line, closing a warehouse, or consolidating suppliers. These tools quantify effects on cost, service levels, carbon footprint, and risk—ensuring subtraction is strategic, not arbitrary.

3. Enabling Lean and Sustainable Outcomes

By integrating lean and sustainability metrics into network optimization, organizations can ensure that subtraction decisions support both operational efficiency and environmental goals. For example, deleting low-value SKUs may reduce transportation miles and inventory holding costs while also lowering emissions.

4. Shielding Users from Unnecessary Complexity

When taking strategic-level decisions, business managers don’t need to be distracted by small details. AIMMS tools (whether out-of-the-box like SC Navigator, built exactly to the business needs) can provide a simple user interface that focuses on the important information for the business problem at hand.

SC Navigator can help you optimize strategic subtraction decisions

One of the main reasons why supply chain leaders love SC Navigator is its ability to work with simplified user interfaces to manage a complex problem:

| Feature | Subtraction Use Case |

|---|---|

| Baseline & What-If Scenarios | Simulate removal of assets |

| Custom Objectives | Minimize total cost or CO₂ |

| Center of Gravity | Identify redundant locations |

| Inventory Optimization | Right-size inventory buffer needs after cuts |

| ForceClose Controls | Precisely exclude sites lanes or products |

| Scenario Navigator | Compare subtraction options |

Here is a great quote from one of our customers using SC Navigator to improve decision-making.

“One of the great aspects of SC Navigator is its ability to efficiently show when ideas won’t work, saving us from costly assumptions.”– Scott Harding, Commercial Logistics Manager at HF Sinclair.

The Dual Mission: Performance and Sustainability

McKinsey emphasizes that leading companies are now pursuing a “dual mission”—simultaneously reducing costs and carbon emissions.

Is that a bad move?

For most manufacturing, retail, or energy brands, this is not a strategic option but a necessity, driven by rising input costs and increasing regulatory pressure (such as carbon taxes and mandatory emissions disclosures). Strategic subtraction or removing inefficient products, processes, or supply chain nodes, directly supports both missions.

Applying a carbon-emissions lens to cost-reduction programs fosters creativity and innovation. For example, rethinking material choices, challenging volume assumptions, and reworking replacement practices can yield both cost and carbon savings—sometimes doubling the impact of previous efforts.

Conclusion

Strategic subtraction is not about doing less. It’s about doing what matters, better.

When supported by a robust supply chain network design and optimization, it enables organizations to do more by doing less. By integrating product deletion with supply chain management, leaders can unlock cost savings, enhance agility, and advance sustainability goals. In turbulent times, the ability to subtract wisely is a key driver of supply chain excellence.

Curious to explore more on how to reach ROI with supply chain design projects and share them with the wider team? Ask our optimization experts today.