Top Insights about Supply Chain Network Design – benefits, tips and what your competitors are doing

What are companies looking for in supply chain network design technologies? What works well, and what are the challenges? We commissioned Supply Chain Insights to conduct independent research about this topic and discussed the findings in a recent webinar. Today, we’re pleased to share a more extensive report on this topic. The report covers perceptions about supply chain network design (SCND) as a process and outlines the key benefits and barriers experienced by companies when using SCND technology. Let’s take a look at some of the key findings.

What is supply chain network design?

SCND is about two things:

- Defining your footprint – what your supply chain should look like, where you should build your next distribution center, where you should locate your next factory.

- Determining how to optimize the flow of goods throughout your supply chain network from source to demand – where do you buy and make goods, where do you store them, and how do you optimally move them through the network.

SCND seeks to maximize service levels to customers, but at a minimum cost. Finding the optimum balance in this trade-off is often what makes SCND a challenging endeavor. You need technology to crunch the numbers, manage data and run optimization models for decision support.

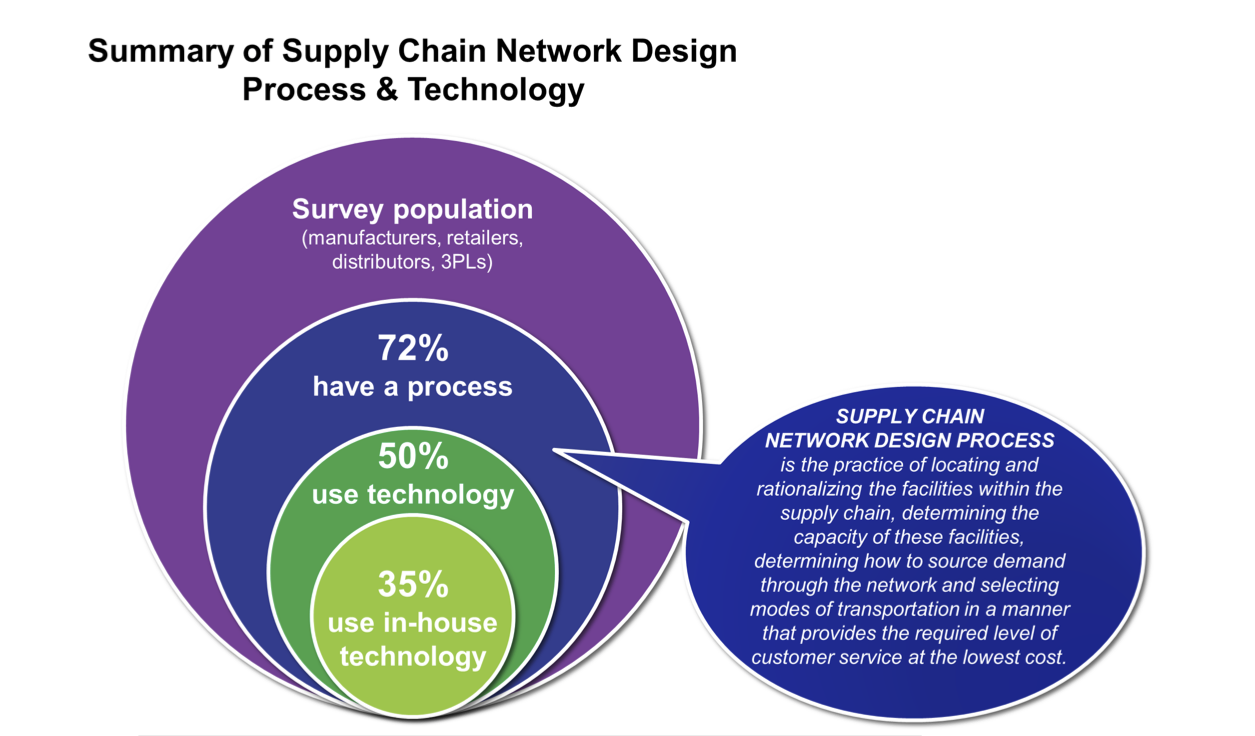

What percentage of companies have a SCND process in place and how effective is their SCND process?

Supply Chain Insights research found that out of 110 survey respondents, 79 (72%) have a SCND process in place. Out of those 79, only 19% rated their process as very effective. Most (44%) rate it as “somewhat effective” and 22% rate it as “not very effective.”

The survey was conducted online among professionals from a variety of industries, including industrial manufacturing, food and beverage, retail, CPG and pharma. The majority of respondents are based in North America and Europe and they hold mostly director-level and managerial positions in supply chain.

What percentage of companies use Supply Chain Network Design technology?

50% of surveyed participants stated that their company is already using technology, with spreadsheets cited as the most commonly used tool. These companies have been using SCND technology for an average of 4 years and have 7 team members on average using this technology in-house. Some of them (37%) rely on consultants to deploy the technology.

What are they looking for in SCND technology?

55% of those surveyed prefer configurability (the ability to customize the technology to business needs and processes) over standardization (11%). Usability and the ability to import/export data are cited as the most important attributes they look for in SCND tools.

What’s hindering them?

Poor data quality (53%) and lack of skilled resources (30%) are cited as the most common obstacles for companies with a SCND process in place. Those without a process stated that lack of skilled resources (58%) and lack of upper management support (35%) were the main obstacles to engaging in SCND.