7 Pitfalls of Stalled IBP Initiatives and How to Overcome Them

Integrated Business Planning (IBP), as defined by its creators at Oliver Wight, is “the business planning process that extends the principles of S&OP throughout the end-to-end supply chain, product, service and customer portfolios, customer demand and strategic planning, to deliver one seamless management process.” IBP provides substantial bottom-line benefits. It fosters employee engagement, customer satisfaction, and alignment throughout the business. When done properly, it also allows organizations to predict and respond to changing conditions quickly.

How can you gain this capability without getting bogged down in a long implementation? What role can technology play in successful IBP adoption? We recently held a webinar with our partners at Oliver Wight to address these questions, covering the most common obstacles companies face when adopting IBP. Let’s explore them below.

Pitfall #1: Not involving the right players

In practice, many IBP journeys start from the supply chain. As our recent supply chain planning research shows, VPs of supply chain and operations typically retain ownership of the planning process as well. However, to succeed at IBP, it’s important to connect the dots and link all functions of an organization together.

IBP ownership belongs to the CEO. Having leadership and ownership from the CEO really helps to get output out of the process. Other reviews (prepared for decision-making versus attending for receiving information) are shared by the owners of each strategy element/pillar. For instance, COOs own the supply strategy, marketing the portfolio strategy, and so forth.

Pitfall #2: Not having a dedicated portfolio management review

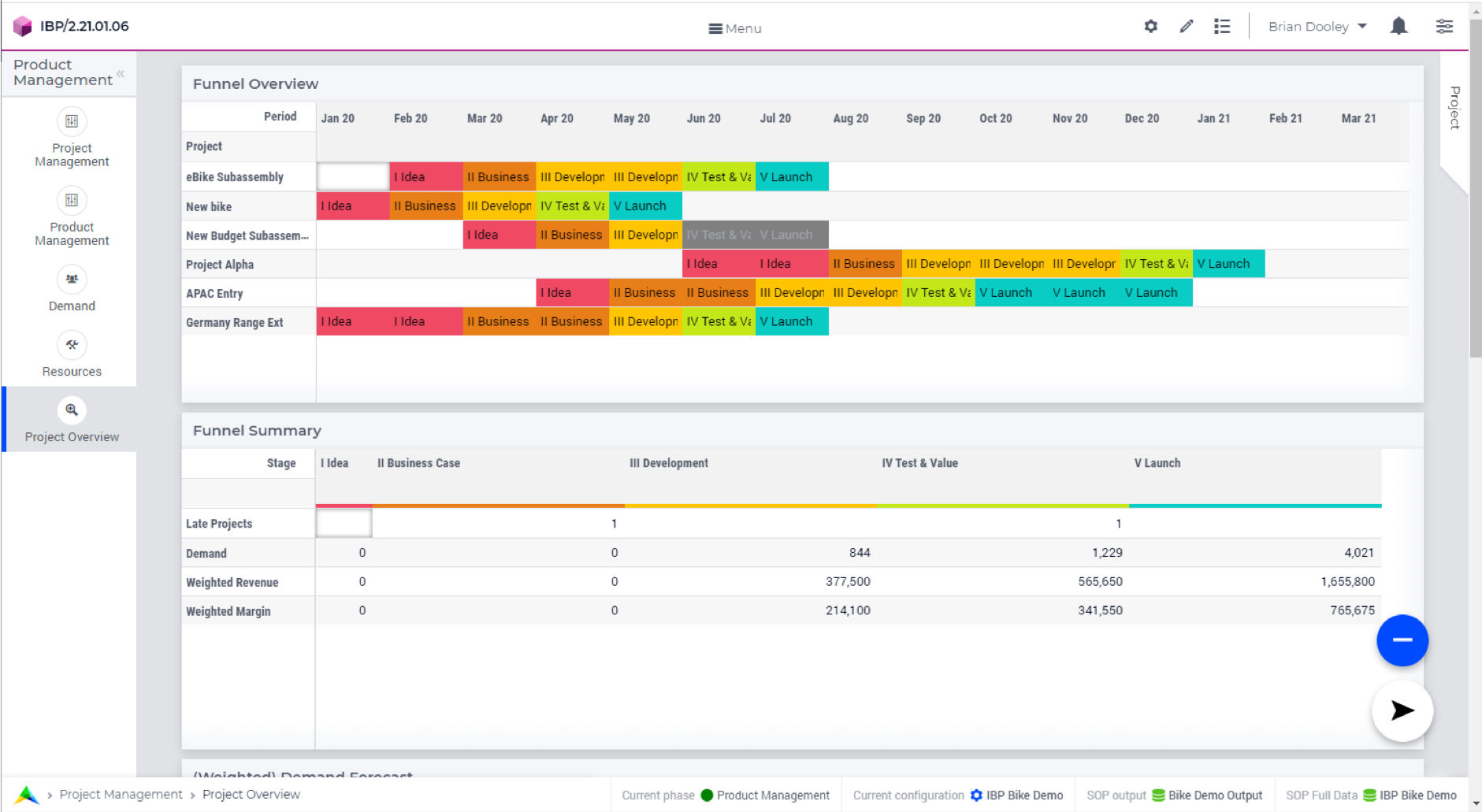

Organizations that rely on Sales and Operations Planning (the precursor to IBP) are typically focused on supply and demand balancing. This leaves gaps in product portfolio management. Having a dedicated portfolio management step helps to have a consolidated view and make integrated decisions on resources, product segmentation, and offerings. However, not all organizations have a dedicated portfolio management review. Additionally, most planning tools fail to incorporate the abstract data that’s required for this stage. How can you account for new products that don’t exist in the master data?

AIMMS IBP allows you to incorporate project management into IBP, enabling you to create new products, manage the various stages in the funnel, and an overview of all projects. You can also assess what your weighted revenue volume margin looks like for different products and carry that forward into the demand review step.

Pitfall #3: Demand is not owned by sales and marketing

Speaking of demand, another common pitfall is having supply chain teams own the demand plan. Often, demand planners are located in the supply chain, where there is more data affinity. As a best practice, sales and marketing should own this part of the process. This process gives sales and marketing teams visibility as to whether they will meet their budget and target requirements, and how they can use their resources most effectively to maximize revenue whilst delivering the commercial strategy.

“Having a tool that allows you to create multiple demand scenarios to evaluate from a supply perspective can remove a lot of the pressure on both sides of the organization” – Tweet this

In this part of the process, teams typically struggle with a lack of transparency and poorly aligned expectations. Supply chain teams look for certainty in a demand plan. In reality, demand is a lot more volatile. This often results in sales and marketing teams refraining from participating or exaggerating their numbers to build a buffer on the supply side. Oliver Wight advises organizations to look at demand from the perspective of “vulnerabilities” and “opportunities.” Having a tool that allows you to create multiple demand scenarios to evaluate from a supply perspective can remove a lot of the pressure on both sides of the organization.

Pitfall #4: Not involving finance in the IBP process

A poll we held during our recent webinar showed that just over a quarter of organizations do not incorporate finance numbers into their planning process. 37% stated that their finance team prepares their numbers typically outside of the process. Keeping financial cycles outside of IBP is detrimental. The info that finance teams need from the business should come from the same stakeholders. Scenarios can play a very important role in overcoming this pitfall as well.

Pitfall #5: Not recognizing that assumptions drive the numbers

Assumptions are the foundation that supports the numbers, so being transparent about them is very important to drive IBP success. If we take COVID-19 as an example, everyone will have different assumptions about how long disruptions will last and what their impact will be. It’s crucial for team members across functions to have a conversation about these assumptions to arrive at a common view. It’s equally important to pinpoint when these assumptions change and make the necessary adjustments to the plan.

Pitfall #6: Working in too much detail

Another common pitfall is losing focus on the big picture. As Oliver Wight explains, it’s better to be “roughly right” instead of “precisely wrong.” Insights from the market should be translated into numbers and discussed at the right level of aggregation to avoid getting dragged down into the details.

Pitfall #7: No alignment with the strategic growth plan

An Oliver Wight survey revealed that 75% of businesses lack the processes to successfully deploy their strategy. Very few organizations regularly assess whether they are delivering on their strategy. Having that forward-looking view of the end goal is key. The right tools can help to assess how you can build towards your strategic plan.

Need help overcoming these pitfalls? Watch the on-demand webinar for more tips and best practices, click on the image below!