Getting Started with Scenario Modeling in Supply Chain Network Design

Scenario modeling is emerging as a key capability in the quest for supply chain resilience. Gartner, for instance, advises companies to “test market sensitivities and elasticities by using scenario planning.” They also recommend that you “reevaluate the scenario planning exercise periodically, as the environment is dynamic and in flux.” In other words, to build your supply chain’s agility and responsiveness, you need to look at scenarios more frequently instead of relying on a single plan. What does this mean in practice? Let’s explore how you can apply scenario modeling in supply chain network design.

Start with the business question(s) and model your base case

Scenario modeling should start with a business question: what are you trying to solve? Once you identify that, you can determine the kind of scenarios you need to run. You will also need to model a base case scenario in order to test your assumptions.

Common network design archetypes to start off

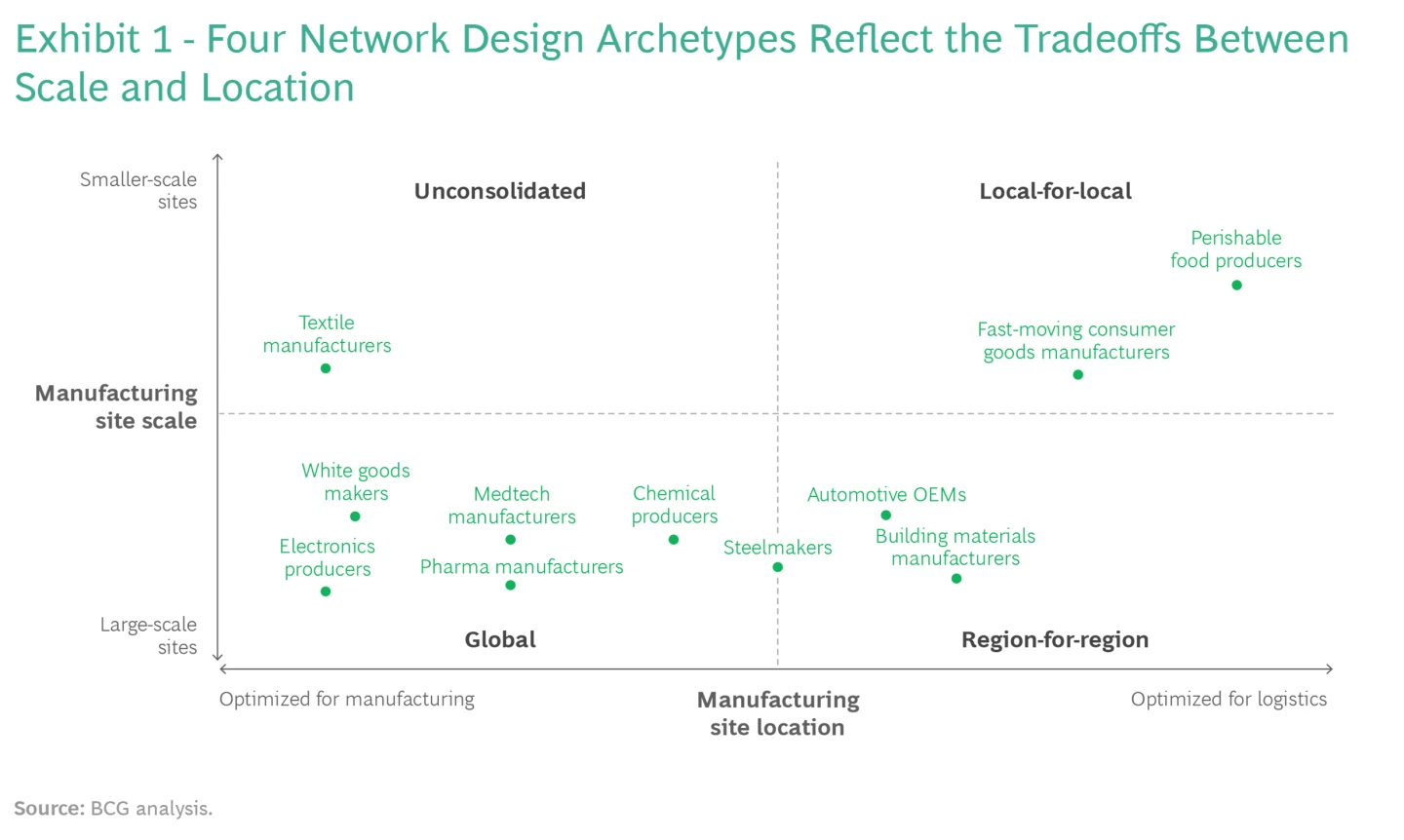

Here is an interesting framework from BCG. To manage the diversity of network design objectives, manufacturers have generally focused on the scale and location of sites for their plants and warehouses.

Over time, balancing the tradeoffs of scale vs location has resulted in 4 network design archetypes or segments across manufacturing verticals:

Global production and distribution are common in industries that are asset-dense and benefit from substantial economies of scale like pharma, electronics, and chemicals. Here, the magnitude of production and minimized operational expenses play crucial roles in cutting costs. Businesses that are heavily reliant on manpower adopt this model, relocating operations to nations known for cost-effectiveness, like Southeast Asia, Latin America, or Eastern Europe.

Local-for-local production and distribution cater mainly to businesses involved in producing items with intricate shipment needs, such as perishable items. Companies in the food and beverage industry for example, often find the need to deliver products to locations in close proximity.

Region-for-region manufacturing and distributing is typically a byproduct of striking a balance between being near the consumer base and ensuring economical production. For instance, industries that consume a lot of energy, like those producing steel or construction materials, often lean towards this model, establishing their operations in areas where they face fewer logistical hurdles and enjoy affordable energy rates.

Unsolicited networks often emerge in the wake of rapid business expansion. As an illustration, post a flurry of corporate mergers or buyouts, a producer might find themselves with an array of smaller facilities which then need to be integrated.

With the increased focus on resilience and sustainability, businesses should re-evaluate the balance between size and geographical positioning to determine their desired equilibrium. This re-adjustment could lead a manufacturer to transition to an alternate model, potentially offering a substantial competitive advantage.

What is a base case scenario in supply chain network design?

Your base case provides the foundation for a digital supply chain twin at the strategic level. It’s a digital representation of your physical supply chain. You need a base case to build confidence (for yourself and the business owners) in your model and ensure it represents reality. We advise our customers to run a base case model and compare it to income statements or other cost data. The base case model should get to within 5% to 10% of actual costs and volumes. Once you have a validated base case, you can start exploring scenarios based on your business questions. The base case will also be a reference point from which you can measure optimization benefits.

More tips in our Guide: Implementing Supply Chain Network Design

Here are some ideas for typical scenarios in supply chain network design

Relax different constraints to identify cost-saving opportunities

If you’re looking to identify cost-saving opportunities, start by relaxing your different constraints.

- Relax transport constraints to see if you can allocate customers to different service locations in order to optimize costs. These are often “low hanging fruit” as they require little or no investment to execute.

- Relax DC capacity constraints to see if you can shift volumes between locations to save costs. This will also reveal how much additional capacity you need to make these shifts, and whether it is worth the CAPEX investment to do this compared to the OPEX savings that can be achieved.

- Relax supplier and production constraints to see if any shifts in supplier and production volumes deliver any cost improvements. In some cases, supplier and production shifts can be done easily without massive investment. In other cases, the opposite is true. Either way, this scenario will highlight the quantum of the shift and the expected OPEX benefits, which can then be weighed up against the CAPEX required.

Assess DC closures and the impact of shutdowns

Prolonged shutdowns had serious financial and operational implications for many businesses in 2020. The effects are often very difficult to assess due to the complexity and far-reaching nature of supply chains. So, it’s not surprising that companies are investigating scenario modeling to explore the potential fallout.

Evaluate potential for reshoring or multi-sourcing

Another popular use case for scenario modeling is evaluating new sourcing locations. A recent Thomas survey found that 64% of manufacturing companies are likely to “bring production and sourcing back to North America” in view of COVID-19. What we’re seeing is not just a trend towards changing materials/part suppliers, but also warehousing and logistics suppliers.

Once you have modeled your current suppliers, resources and customers, you can model new suppliers in your own country (or a neighboring country) and identify which supplier you should select for an optimal cost scenario.

Run demand flex scenarios

You can also optimize for the future by running some scenarios against projected future demand. These projections may not be accurate, but you could run high growth / low growth / expected growth scenarios to put some confidence bounds around your forecast.

Modeling the impact of carbon costs in supply chain network design

Traditionally, supply chain network design focused on optimizing costs and service levels. However, another dimension will require more attention going forward: designing for sustainability and responsible business. Some companies are already experimenting with carbon costs. Typically, you convert carbon tons to carbon costs, change them into cost coefficients per unit of activity, and then incorporate them into your model to start running scenarios. For example, you can compare scenarios to see how much additional physical costs you would incur if you optimized to reduce carbon costs.

There are many other scenarios that can be run. The list above should provide a good starting point to explore optimization opportunities.

Finding the right tool for scenario modeling in supply chain network design

If you’re looking to adopt scenario modeling in supply chain network design, you’re likely going to evaluate the different tools available as well. Your consideration set may include spreadsheets, working with a consultant, and/or software vendors like AIMMS. The technology and approach that you choose should vary depending on the level of complexity in your supply chain. For instance, if you have a very large and complex network, combining scenario planning with optimization can help you understand the different trade-offs in a more holistic way.

Watch our 30-minute webinar “Supply Chain Network Design: What are Your Options?” to explore the main technology types in the market.

What our readers are saying

Comments are closed.

Thank you for the article!