Supply Chain Design: Don’t be afraid to get the data

Do your supply chains count multiple Distribution Centers (DCs), warehouses, production sites, suppliers, customers, and various products and transport means?

Optimizing this network takes quite some effort and knowledge. A fair share of this work involves getting the data and transforming it into the correct format. That sounds like a daunting job, right? With multiple data sources and formats, it can become an overwhelming endeavor. But no worries, let us help you to get started. Once done the reward is in running your scenarios to quickly identify opportunities in your network!

It’s there but needs some work…

An optimized network design is accomplished through data. But what do we mean by optimized? For example, data about the exact locations of your assets, the expected product demand, the transportation costs, and the loading volumes of your various transport means.

Yes, I sense your hesitation. Where do I get all this data from and how do I get it in the right format so my supply chain design technology can do its magic by showing me the outcomes of different scenarios?

The good thing is that this information is available in your existing data troughs such as your procurement system, financial system, order management system, or combined in an ERP (Enterprise Resource Planning). Other data is available externally, i.e. geo-location data or truckload volumes.

Converting this data in the right format so your supply chain design solution can perform its computations, needs some work.

Which data?

To start with network design, the first thing to accomplish is setting up your ‘base case’, in other words, your current network with all your assets in a digital format. From there you can run scenarios with different variables and objectives leading to certain outcomes.

When you become more advanced working with a scenario modeling tool, more data is needed and more models are created. For building your base case, however, you’ll need a minimum amount of data about your network. Let’s explore those, with their formats needed.

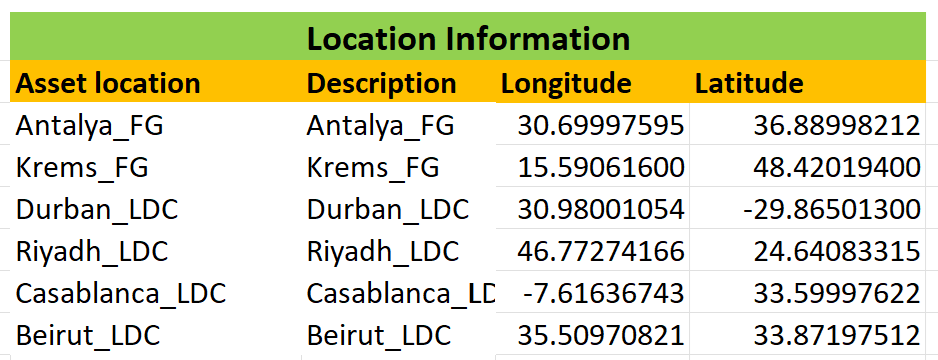

1. The exact location of your assets

As you can see in the table below, for each of your assets (i.e. a distribution center, a warehouse, a production site, or a supplier), the geographic coordinates are needed. This data is publicly available for each address worldwide.

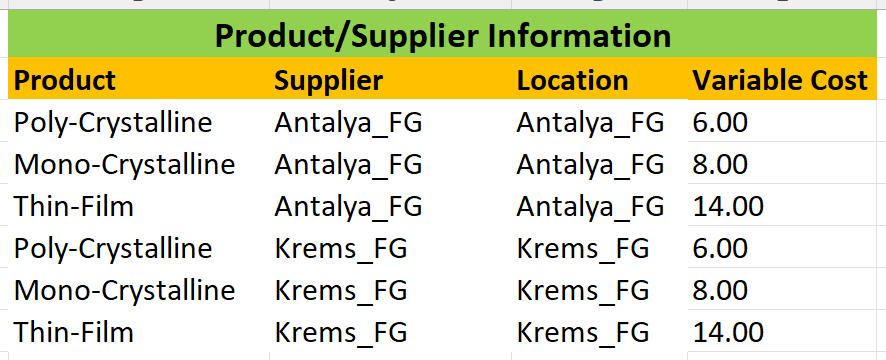

2. Product costs per supplier

To be able to calculate what is the best supplier of your materials for certain products, you need some cost information per supplier and product:

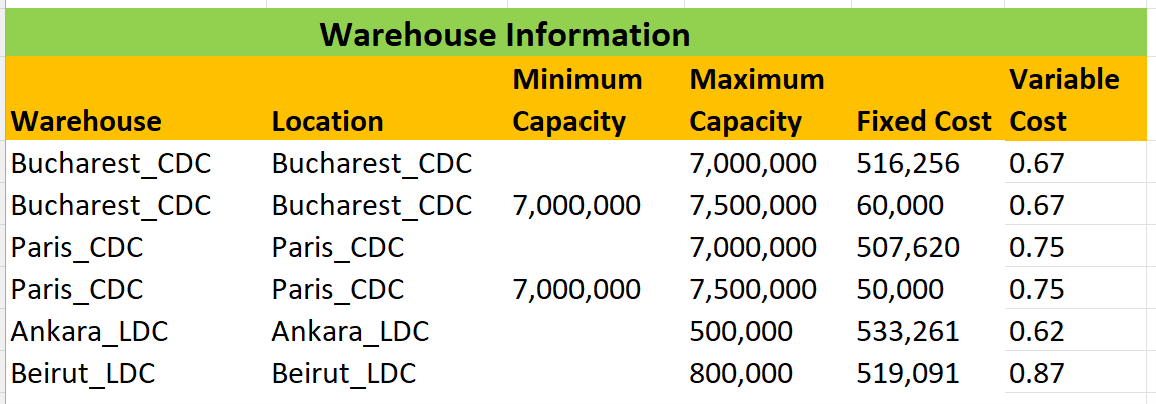

3. Warehouse information

3. Warehouse information

For each warehouse or DC provide capacity information, fixed costs, and variable costs. With this information, the system is able to determine where the goods should be stocked and how much.

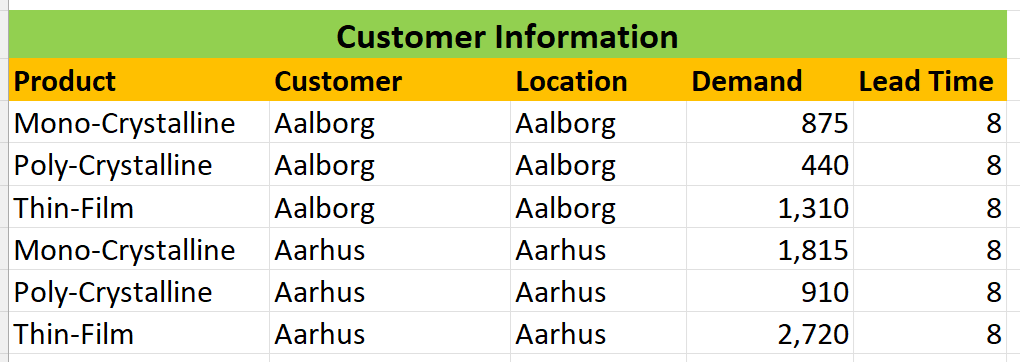

4. Customer information

The demand with the lead time per product is needed per customer to determine the location and size of demand, and the proximity service levels that need to be met.

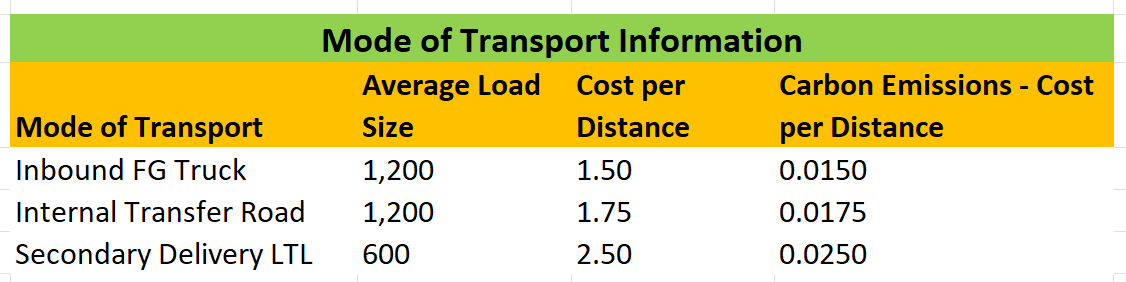

5. Mode of transport information

In this file, specific information will be stored per transport modality so that the system is able to determine the optimal transport mode or vehicle for a certain trajectory in the supply chain.

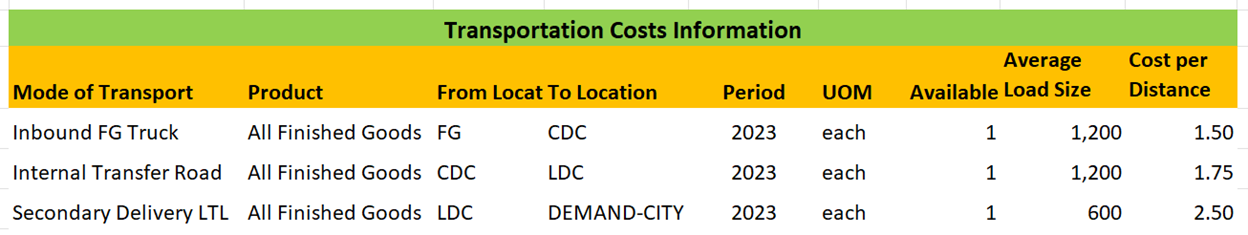

6. Transportation costs

You will also need the transport cost per modality to move the products through the supply chain.

Three data delivery options – Excel, ETL, or outsourcing

When using advanced supply chain design technology, like AIMMS SC Navigator, there are three options to feed the system with data:

- Prepare the data in Excel files for upload

- Retrieve the data via a built-in interface to the source of the data, this is usually an ERP system or a data warehouse (ETL)

- Outsource the data work using our data & modeling services where we do the heavy lifting for you preparing the data and setting up the models while you run the scenarios and analyze the results.

AIMMS has thorough experience with each of these options. You choose which fits your situation best. To help you further we recommend you read a series of blogs that provide tips and tricks for network design data preparation and collection –

- Data Tips for Supply Chain Network Design Part I: Preparation

- Data Tips for Supply Chain Network Design Part II: Data Collection

You’re almost there…

We hope you feel more confident getting your data sorted and that you learned that this part of starting with advanced network design technology shouldn’t hold you back. In the next blog, we will talk about creating models, the second task to be done once your data is sorted and before scenarios can be run. Once your models have been set up, you’re ready to compare countless scenarios, visualize them on a map, and facilitate quicker decision-making about making changes in your network in these turbulent times.

For more supply chain network design implementation tips and tricks download our guide.