Invest in These Capabilities to Drive Supply Chain Excellence

Insights from Gartner’s Hype Cycle for Supply Chain Strategy, 2020

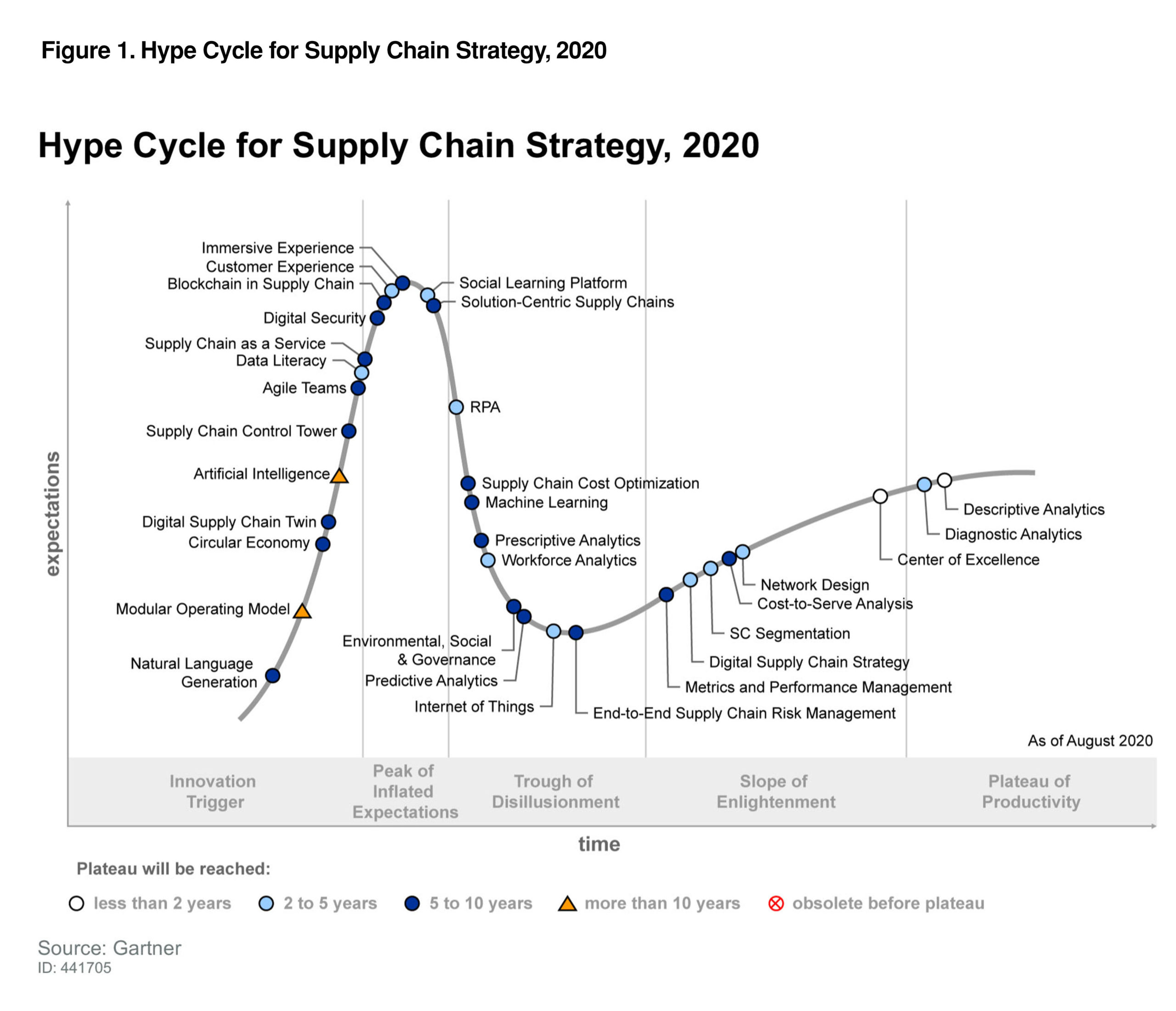

Supply chain professionals know it can be extremely challenging to drive day-to-day operational excellence and pursue innovation at the same time. Our recent survey showed that only 17% of organizations make it a priority to invest in innovation. Firefighting is the norm. It can also be challenging to decide where to invest. Gartner’s Hype Cycle for Supply Chain Strategy, 2020 offers some guidance. The report outlines the tools with the highest transformational benefits and capabilities that are becoming standard business practices.

What to prioritize

In the report, you will find capabilities across five categories: technologies, competencies, frameworks, operating model strategies, and organizational models. You’ll also find a priority matrix that can help you identify opportunities based on their impact and maturity level. As Gartner explains, “Organizations are looking to scale their adoption of tried-and-true capabilities, on the right side of the trough (Gartner, Hype Cycle for Supply Chain Strategy, 2020, Noha Tohamy, 6 August 2020).” These tried-and-true capabilities include a Digital Supply Chain Strategy and Network Design.

Adopting capabilities “whose benefits are categorized as transformational or high that will plateau in five to 10 years in the priority matrix is critical to future competitiveness.” These capabilities include Machine Learning and Prescriptive Analytics, and organizational models like Agile Teams.

AIMMS in Gartner’s Hype Cycle for Supply Chain Strategy, 2020

Where does AIMMS fit in the Hype Cycle? Gartner mentions us as a Sample Vendor in two categories: Network Design and Prescriptive Analytics.

Network Design

Gartner defines Network Design as “the creation of a supply chain model to optimize the network for chosen strategic objectives.” There are many drivers for the adoption of network design, but we have seen increasing interest in this capability with companies striving to build resilience amid COVID-19 disruption. As the report explains, “In volatile business environments, companies using an analytics-driven approach to designing their supply chain can better assess trade-offs between conflicting priorities.” Gartner advises companies to “prioritize the ability for scenario planning to be conducted more frequently,” as it can improve decision-making. Use cases include analyzing the impact of Supplier and DC closures and shutdowns, planning for steep demand decreases and increases, evaluating potential reshoring, and assessing potential network investments with scenarios.

While clients have been using AIMMS to build their own network design applications for decades, our off-the-shelf and easy-to-use network design applications are growing in adoption.

A major flavors and fragrances company used AIMMS Network Design to rationalize their network after a merger. A healthcare devices company leveraged the software to optimize their network and went from gut-based decisions to looking at different scenarios and gauging the impact on costs, risks, and customer satisfaction. The analyses helped them make an investment that made them more resilient to face the pandemic. A logistics company used AIMMS to address constraints due to COVID-19 and was able to deal with the situation in an agile way. A leading Telecom company uses AIMMS to minimize the drive times of their field engineers to pick up spares.

These customers appreciate the rapid deployment and how easy it is to use the software to identify new areas of improvement by tapping into side-by-side scenarios and what-if modeling capability. Prescriptive Analytics is the foundation that powers this, and the technology that rests at the heart of the AIMMS platform.

Prescriptive Analytics

Prescriptive analytics “describes a set of analytical capabilities that finds a course of action to meet a predefined objective, such as maximizing revenue or minimizing costs.” This type of analytics augments a user’s decision-making and has a significant impact on the supply chain. Our customers have built prescriptive solutions for strategic business planning, tactical planning (S&OP), logistics and warehouse optimization, capacity planning, maintenance planning, production scheduling, crew planning, asset optimization, price optimization, and other applications.

Although we are not mentioned under Machine Learning, we have been investing in this capability to enhance our applications. For instance, AIMMS Demand Forecasting uses sophisticated machine learning to help users find the best statistical model to forecast demand, and automatically chooses the correct amount of history to generate the most accurate statistical forecast. The machine learning algorithm then continually fine-tunes the forecast model through each forecasting cycle. This is a great example of how machine learning can improve productivity and free up resources from time-consuming tasks.